- Providing vehicle analysis through teardown

|

||

Strategy Analytics, a global market research firm, predicted that the global service robot market would grow from $31 billion in 2019 to $122 billion in 2024. In this service robot growth trend, logistics robots are expected to form a $7.5 billion this year.

Against this background, there was the development of AMRs through autonomous driving technology. The existing unmanned transportation system consisted of many logistics robots moving along a line pre-drawn with AGVs. On the other hand, AMRs can transfer logistics without being constrained by already defined lines. Since it can create its own route, it can be used in factories with many obstacles and department stores or exhibitions where many people move around. There is a company that provides advanced conveying solutions built based on this technology: Fusion.ENC.

|

Introducing MOOVON, a heavy load automated omnidirectional transfer robot platform

Founded in 2017, Fusion.ENC Co., Ltd. is a company that has started developing and manufacturing vehicle-related solution models and is currently providing automation equipment and logistics-type robot vehicle drive mechanism technology solutions.

The company has developed a ride-on ball robot with rich experience in vehicles and machinery, and has been selected as one of the top 10 machine technologies in Korea together with Kyung Hee University. It is registered as a partner of POSCO, Korea Space Airlines, Korea Institute of Robotics & Technology Convergnence, and Korea Advanced Institute of Science and Technology. By using its accumulated technology, Fusion.ENC developed MOOVON, a heavy load automated omnidirectional transfer robot platform.

|

MOOVON is an autonomous transport robot platform capable of carrying heavier loads than other similar conveying robots. The L.O.D (Lift type Omni Directional Robot), for example, can load up to 500kg and its seizure lift makes vertical motion and leveling easy with more reachable performance. It is equipped with LiDAR and vision sensors, and an automatic route system. LiDAR sensor is a sensor with high detection response speed. The vision sensor recognizes the position and shape of multiple objects in a three-dimensional space, allowing it to change its route or stop driving. The automatic route system is an autonomous driving technology that changes the route to the destination by reflecting work environment information in real time. If you repeatedly move and rotate the omnidirectional platform manually while driving, you may lose your awareness of the reference direction. MOOVON, on the other hand, has secured the ability to control the direction from the center of the pilot to compensate for this situation.

|

| ▲ Fusion.ENC / CEO Kim Hyun Jin |

From larger, heavier weights to modular types according to their needs

Vehicle analysis service through teardown

Fusion.ENC has also developed L.H.T (Lower type Heavy duty Transporter) model that can load up to 3,000 to 5,000 kg. Like the LOD model, the LHT model assists workers through indoor location recognition technology, autonomous driving reflecting work environment information, and pilot-centered device control algorithms.

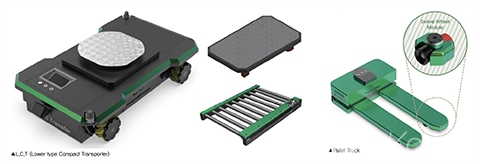

Meanwhile, L.C.T (Lower type Compact Transporter) is an omnidirectional transfer platform that can replace the upper board. This is highly usable because it uses a module system that exchanges the scissor lift, conveyor, and turntable board according to the transfer method and use. It is also possible to collaborate by tracking while maintaining a certain distance from the user, who is a worker, and can maximize efficiency and productivity by enabling efficient use even in a narrow space by using Mecanum wheels that can be freely switched in all directions.

In addition, Fusion.ENC is in the process of completing the development of the M.L.T (Mega Load Transporter) Platform, which can load and transport up to 5,000 to 30,000 kg, which can be used in steel mills, railway vehicles, and aircraft manufacturing sites. The M.L.T product group can customize the platform structure and functions according to the requirements of the end user, and has a structure in which two or more transfer robots can communicate with each other and move as one robot through synchronized driving to further increase the load capacity of the heavy load.

The company’s vehicle analysis service collects data according to the trend of the times by accurately analyzing materials and structures through detailed teardown. The Teardown analysis provides customized data to study vehicle technology of competitor companies, parts, and cost reduction factors.

A company official expressed their ambition to become a trusted company by developing into a first-class domestic and foreign company by providing design and manufacturing of industrial automation machines and leading new technologies.

권동호 기자 dongho2010@naver.com